Each FX Dialyzer is individually sterilized by the unique INLINE steam sterilization method. Both the blood and the dialysate compartments of the dialyzer are rinsed continuously with steam at a minimum temperature of 121° C, followed by sterile water and sterile air.

Rinsing with hot steam assures a gentle sterilization — without the need for chemicals or irradiation, which may lead to increased cytotoxic14 and carcinogenic residuals.15,16

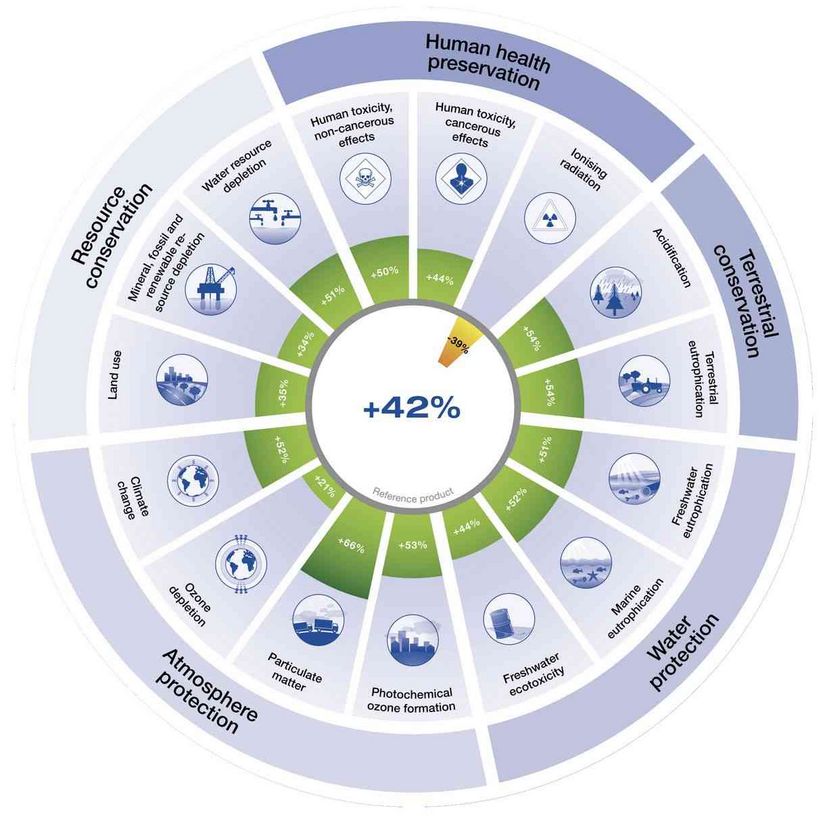

Optimal use of resources

The INLINE steam sterilization process allows for the efficient use of resources during preparation as well as a reduction of costs, since only 500 mL rinsing volume is required. The process

- includes a 100% fiber integrity test, aimed at minimizing the risk of blood leakages due to fiber ruptures

- ensures that all FX Dialyzers are already pre-rinsed and ready to use upon arrival, resulting in short rinsing time and low rinsing volumes.

Best choice for high biocompatibility

Cytotoxicity is minimal after steam sterilization, whereas it increases with gamma irradiation.14 Studies have shown that with steam sterilized dialyzer membranes, less oxidative stress is induced to the patient’s blood compared to gamma sterilization.17,18,19

Performance characteristics remain intact

Changes of the material properties can be observed after sterilization with gamma irradiation, while the material remains intact in this respect when using steam sterilization.20

Increased losses of albumin during dialysis sessions have been observed with gamma sterilized dialyzers which were stored for a longer time.14,21